Engineering Plastic New Energy Extrusion Plastic Raw Materials FEP Resin for Tube, Pipe, Rod, Sheet with Factory Price

Basic Info

| Model NO. | YT503 |

| CAS No. | 25067-11-2 |

| Formula | {[C2f4]N[CF3]}M |

| EINECS | 25067-11-2 |

| Molecular Principal Chain | C-F Chain |

| Color | White |

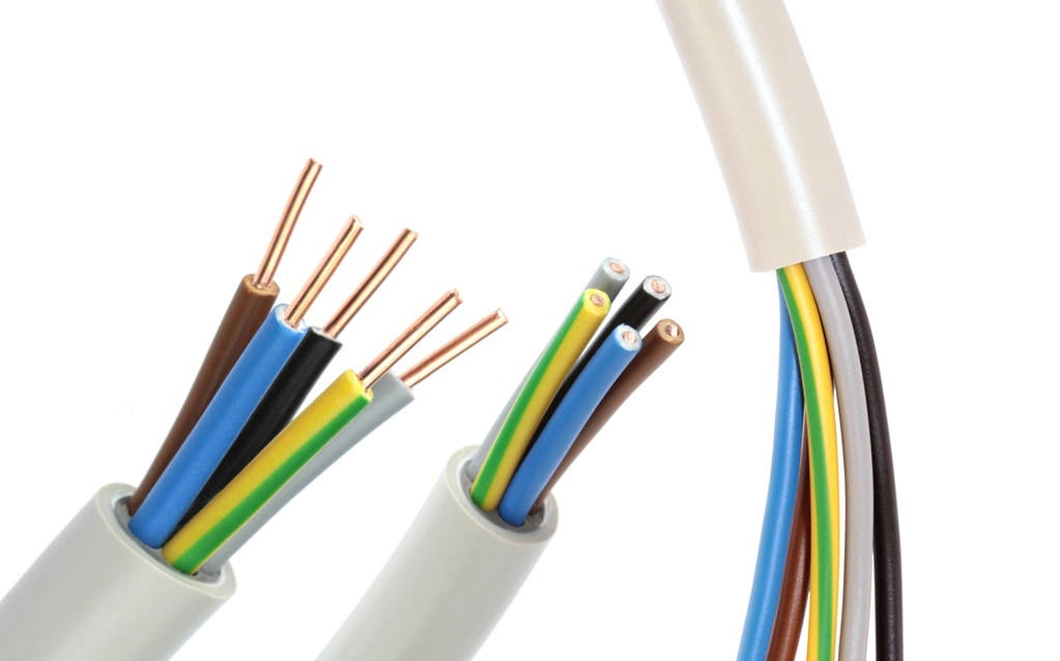

| Application | Insulation Jacket of Wire, Membranes |

| Mfr | 12.1-20.0 |

| Melting Point | 265 |

| Sample | Free |

| Transport Package | Bag |

| Specification | FEP |

| Trademark | FeiTengYa |

| Origin | China |

| HS Code | 3904690000 |

| Production Capacity | 15000tons/Year |

Product Description

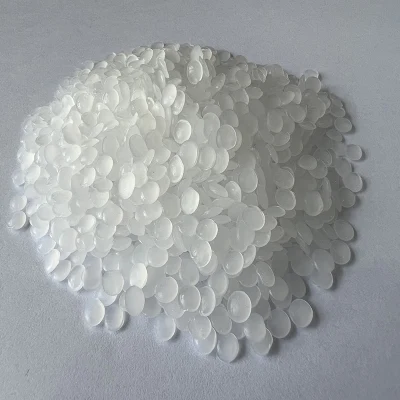

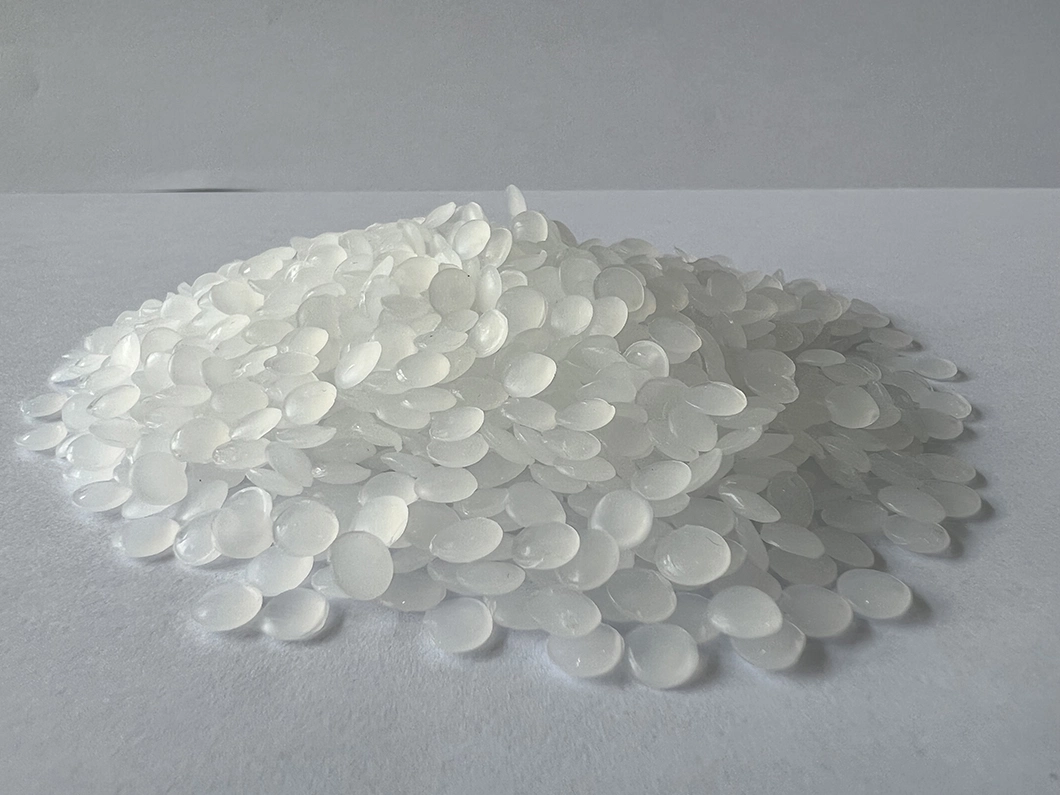

FEP Resin: YT503FEP is the copolymer of TFE and HFP,it has good thermal stability, excellent chemical resistance and electrical insulation. It can be processed by conventional melting extrusion, injection molding, blow molding and other processing technologies. It is widely used in communication, petrochemical, aerospace and industries. Product Parameters

| ITEM | YT501 | YT502 | YT503 | YT504 |

| Appearance | White translucent particles | |||

| MFR ( 372ºC,5KG ), g/10min | 1.0-3.0 | 3.1-10.0 | 12.1-20.0 | 20.1-30.0 |

| Tensile Strength (23ºC) , MPa ≥ | 28 | 26 | 22 | 18 |

| Elongation at break (23ºC) , ≥ | 300 | 300 | 300 | 300 |

| Relative density (25ºC) | 2.12-2.17 | |||

| Melting Point, ºC | 265±10 | |||

| Dielectric constant, 106Hz, ≤ | 2.1 | |||

| Volatile, %, ≤ | 0.5 | |||

Wuhan Feitengya Chemical New Material was established in 2008 in Wuhan. It is an expert in the supply of fluororesin in the whole industry chain integrating scientific research, development, production and sales.Feitengya takes high-end materials (PVDF, FEP, PFA, ETFE, PTFE, PCTFE) as the core and extends to the entire industrial chain such as lithium battery new energy, photovoltaic new energy, environmental protection, 5G industry, coating field, wire and cable, pharmaceutical fine chemicals, aerospace, and automobile fields. Established a good long-term strategic cooperative relationship with many well-known brands, college laboratories, research and development institutions, and production bases around the world, and built a huge production capacity system. The company adheres to the customer-centric and is committed to the development concept of continuously creating value for customers , perceived responsibility, high-quality return, win-win cooperation!

Main Application

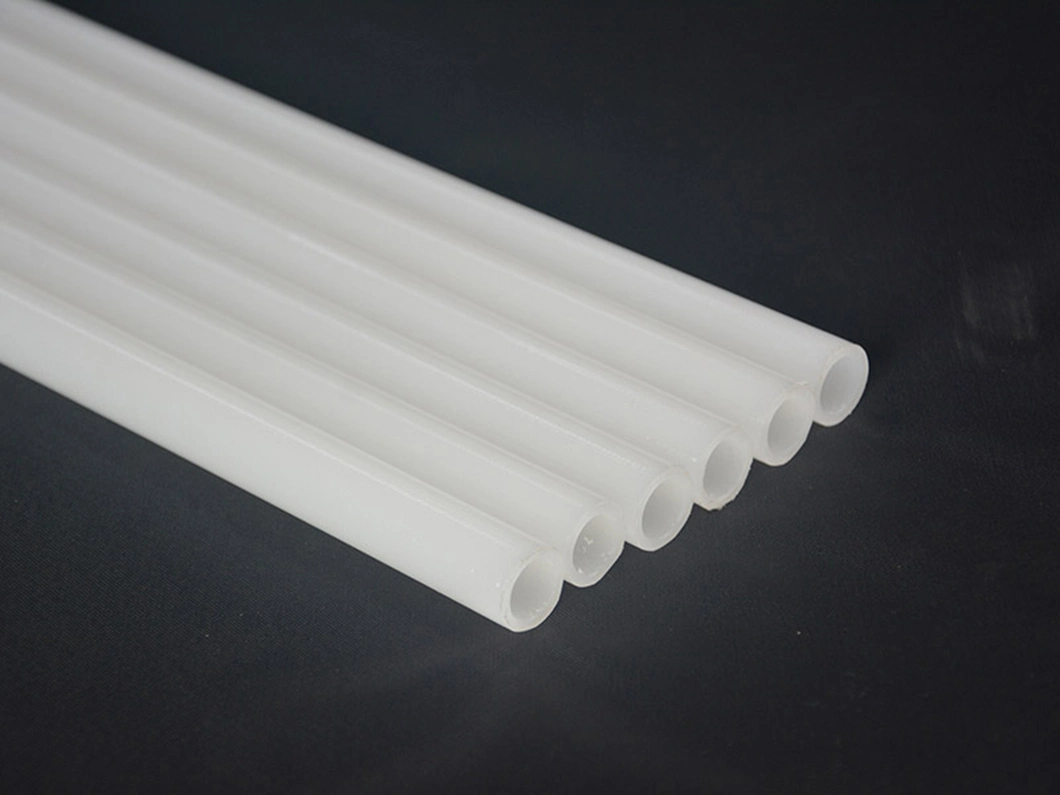

YT501:Mainly used in pipeline, pump valve lining, diaphragm, joints, pressure container lining, etc., suitable for high stress cracking processing;

YT502:Mainly used for insulation jacket of wire, membranes and other products;;

YT503:Extrusion processing of general plastics, mainly used in new energy injection parts, communication and thin wall pipe and other fields;

YT504:Mainly used for electronic wire, high frequency wire and other cable processing, suitable for low stress cracking resistance of high-speed extrusion of small diameter wire insulation materials.

Packaging & Shipping

Package, transportation and storage

1. Packed in plastic bag with inner PE bag of 25kg net; 2. Stored in clean, cool and dry places to avoid contamination 3. Non-toxic, non-combustible, non-explosive, non-corrosion, according to the transport of non-dangerous goods.AttentionThe process temperature should not exceed 420ºC, to provent PFA decomposition and equipment corrosion.