Zhongci Food Grade 001*7 Acidic 732 Cation Exchange Resin for Softening Water of Power Plant Electric Standard Hotel Boiler Resin

Zhongci Food Grade 001*7 Acidic 732 Cation Exchange Resin for Softening Water of Power Plant Electric Standard Hotel Boi

Basic Info

| Model NO. | zc-ier |

| Color | Yellow |

| Appearance | Granulars |

| Type | Water Treatment Chemical |

| Transport Package | 25liter/Bag, 1cu. FT/Bag |

| Specification | 0.35-1.85mm |

| Trademark | Zhongci |

| Origin | China |

| HS Code | 39140000 |

| Production Capacity | 10000ton/Year |

Product Description

Zhongci Food Grade 001*7 Acidic 732 Cation Exchange Resin for Softening Water of Power Plant Electric Standard Hotel Boiler Resin001×7 is a high capacity premium grade bead form conventional gel polystyrene sulphonate cation exchange resin designed for use in industrial or household water conditioning equipment, Its acidity is similar to some inorganic acids,such as sulfuric acid [H2SO4] .It can be used as ion exchanger in alkaline,neutral and acidic mediums.This product has speedy exchange ability and good physical strength.This product is equal to :Amberlite IR-120,Dowex-50,Lewatit-100,Purolite C100EFG2. Executing standard:GB/T 13659-2008 DL/T519-2004

Typical Physical and Chemical Properties:

| Items | Specification | |

| Polymer Matrix Structure | Crosslinked Polystyrene Divinylbenzene | |

| Physical Form and Appearance | Yellow color beads | |

| Functional Groups | R-SO3¯ | |

| Ionic Form ,as shipped | Na+ | |

| Total Capacity, Na+ form, wet, volumetric | ≥1.9 EQ/l min | |

| Moisture Retention, Na+ form | 45-50% | |

| Particle Size Range | 0.3mm-1.2mm or 0.3mm-0.6mm | |

| <300 µm (max.) | 1% | |

| Uniformity Coefficient (max.) | 1.6 | |

| effective size | 0.4-0.7mm | |

| Reversible Swelling | Na+ → H+ (max.) | 10% |

| Ca2+→Na+(max.) | 5% | |

| Shipping Weight (approx.) | 770 -870g/l | |

| Specific Gravity, moist Na+ Form | 1.27 | |

| Temperature Limit | 120°C (250 °F) | |

| pH Range, Stability | 7.5 - 9.5 | |

| Color | 25APHA | |

| COD | <1.0Mg/L | |

It is used in hard water softening,pure water manufacturing, hydro-metallurgy, rare elements separation, aminophenol extracting, widely used in water treatment, sugar manufacturing, pharmacy, monosodium glutamate, hydro-metallurgy industries and so on.Suggested Operating Condition

| Maximum Temperature | Na+ Form | 120°C (248oF) max. |

| H+ Form | 100°C (212oF) max. | |

| Backwash Rate | 25 to 50% Bed Expansion | |

| Regenerant Concentration | Hydrogen Cycle | 3% HCl or 2 to 3% H2SO4 |

| Sodium Cycle | 6% to 8% NaCl or 3% NaOH | |

Regenerant dosage | HC1 or H2SO4 | HC1 or H2SO4 volume:resin volume =3:1 |

| NaCl | NaCl volume:resin volume =2:1 | |

| NaOH | NaOH volume:resin volume =3:1 | |

| Regenerant Flow Rate | 2 to 4 BV/h | |

| Regenerant contact Time | At least 40 minutes | |

| Service Flow Rate | 10-25m/h | |

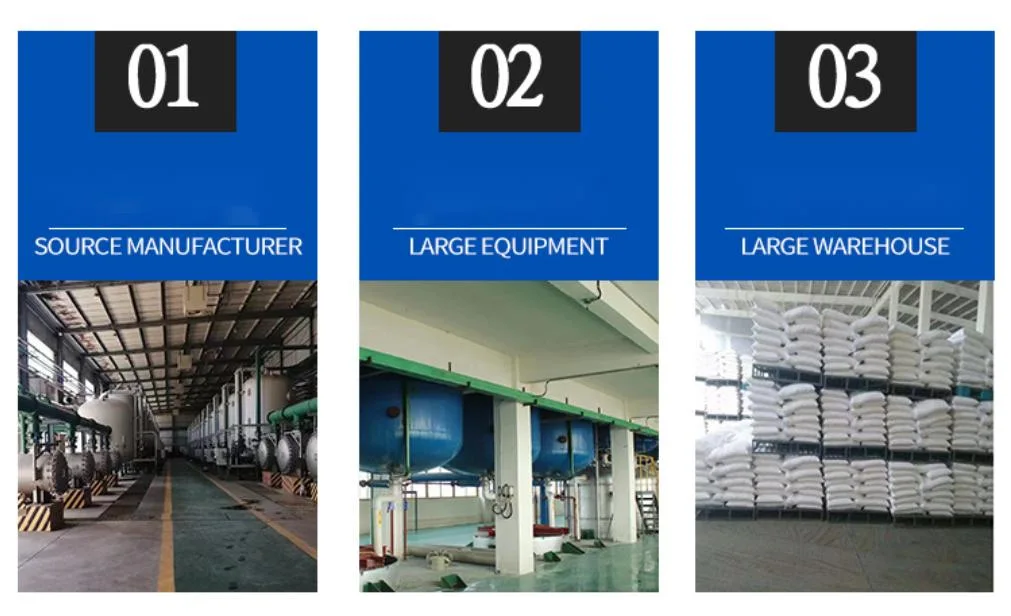

Company InformationPackage&Shipping

Send to us